if you all you have is a laser printer then make sure to spray your vellum or laser acetate down with a “toner black” or stock sprays that made the toner darker.

#Color separation in coreldraw x7 registration

This is why much of the screen print world has gone to inkjet printers with software rips because the black is much denser and there are no registration issues.īut…. In order to really burn a small halftone dot you need dense black on your vellum or laser acetate. Inkjet printing is obviously a better choice for perfect registration and much better films. If using vellum or laser acetate to burn screens, try pre-shrinking the blank pages by running them through the laser one time BEFORE imaging them – to improve registration and minimize shrinkage. Do this by making the underbase plate a 60% tint of black and then output it as halftone dots. Other images that have more shading and gradations, print easier and feel better if the underbase is actually halftone dots. Some images that are solid spot colors need a solid white underbase. For better on-press registration, you should make the underbase from 2 to 4 points “skinnier” – the opposite of a trap.

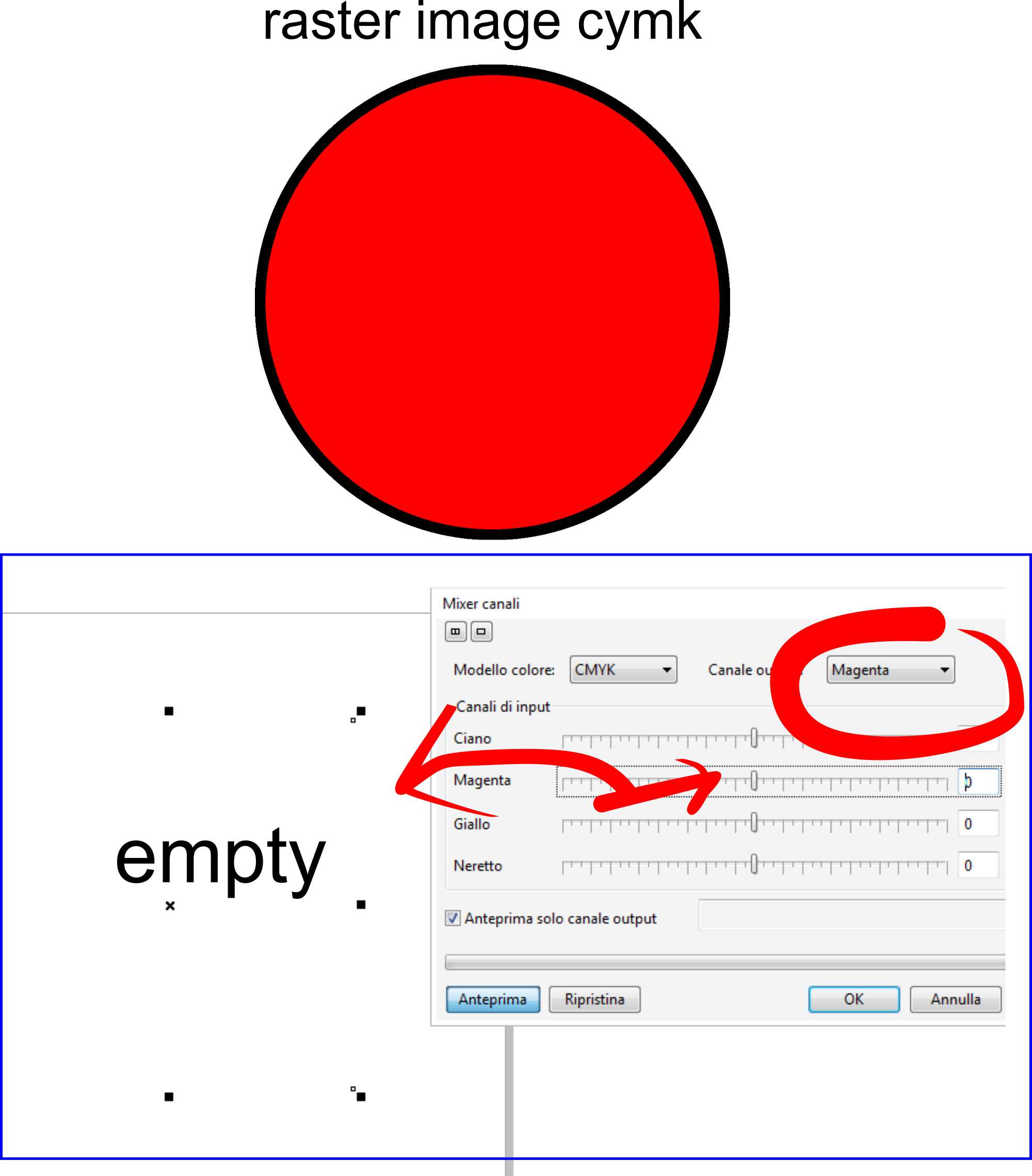

This is generally the entire image converted to one color. When printing on dark shirt colors, you need a base plate of white. If you scan at the default scanner setting of 72dpi you will have a very jagged edge when you take the image to Corel Trace.Ĭhoke underbases for better registration. When scanning line art, scan at resolutions of 800 to 1200 dpi in order to have your tracing program like Corel Trace give you a much more accurate bitmap to vector conversion of the image. This way your films will not only have a nice solid registration target for each film but the film will have the exact ink color of that film. That means they will print on each separation.Īt the same time, put the name of each color on the top of the file using the same exact spot colors you use in the file. Make your own custom targets and assign them a color of “Registration Color”. The “stock” registration targets in all programs are generally too small and you don’t have any control over their placement. What looks great on the monitor will look much darker when screen printed. You need to allow for this by using a lower percentage tint in shading areas so when it is printed it will look correct.

When you print a halftone dot, it will grow in size 30% to 50%. If using halftone dots or tints of color in an image, when output, these areas are made up of small dots called halftones. Trapping happens in the rip during out put. In order to have a trap print out of Corel correctly you need a printer with postscript or a software rip. If you gave the text a six point outline then the trap will be 3 points. I will cover this in detail in a future article but for now, it is as simple as selecting and object and holding down the right mouse and selecting “overprint object”. Figure 2Ī trap is generally done by adding an outline/stroke to undercolors (other than black) to make them slightly fatter. If you spend time adding traps, images will appear to be in register when they are not. A trap can be as small as 2 points for shops that can hold tight registration, or as big as 6 points for simple images on low-end equipment. Trapping is the overlapping of darker colors (like black) on top of undercolors. If your “films” are output on a laser printer, they many never line up. When printing spot colors, any out of registration will show up as gaps between colors. The funny thing about printing shirts is that sometimes spot color images where colors touch colors are often HARDER to print than photo realistic images made up of halftone dots. Vector based programs like Corel Draw, Adobe Illustrator and Macromedia Freehand are generally used for spot color images or images with a hard edge and more of a cartoon look. Others are just good nuts-and-bolts suggestions that can make or break a set of seps.

#Color separation in coreldraw x7 manual

In order to fit this in the allotted space, many tips are brief suggestions that will require referring back to your software manual to figure out. This article lists a few quick tips for better separations and art output which leads to better prints. – but it all starts with color separations. Yes, yes, you need to use properly tensioned screens, good press setup, proper ink viscosity, etc. As you become a better printer, it doesn’t take long to learn that in most cases if the separations are done correctly, the print looks great. Over the years I have learned that one of the major secrets to good screen printing is good color separations.

0 kommentar(er)

0 kommentar(er)